How Much Air Needs To Circulate In Clean Room?

Why Can't Anyone Hold on Benchmarks for Cleanroom Air Change Rates?

At that place are a number of best exercise guides and benchmarks for cleanroom air change rates (ACR). Many of which reference charts dating back as far as 20+ years. About commonly referenced are ISO 146144-iv for hourly air changes and air velocity rates, and Federal Standard 209E for fan filter ceiling coverages.

Many charts constitute on the internet reflect a gray interpretation of industry benchmarks, or sometimes data found in "outdated" standards. Many of these charts combine results and graphics from the beneath documentation.

- IEST-RP-CC012

- ISO 14644-4: Blueprint, Structure, & Start Upwardly

- Fed. Standard 209E (Outdated)

- ASHRAE

What Makes Computing Cleanroom Air Change Rate Confusing?

- Data is outdated, incomplete, or missing/mixing context

- Improper adding method for cleanroom in question

- Failure to adjust for inputs, such as ceiling acme or directional menses

- References to outdated or non-scientific standards.

Why is Cleanroom Air Change Rate Important?

Air change rates are important factors in determining the blueprint and performance criteria for a cleanroom HVAC system. The full rate, flow pattern, and commutation efficiency have far-reaching implications on cleanroom performance and cost. The performance and cost eventually make up one's mind the rate-of-return on investment for a cleanroom.

Airflow engineering is the main method of contamination control for both feasible (living) and not-viable particles or microbes. However, information technology'due south too a primary requirement for the condolement and condom of a cleanroom'southward about prized producers: its operators.

ISO Definition of Cleanroom Air Commutation Rate

As defined by ISO 146144-4 standards: rate of air exchange is expressed every bit the number of air changes per unit of measurement of fourth dimension and calculated by dividing the book of air delivered in the unit of time by the volume of the cleanroom or clean zone.

How to Choose the Proper Air Change Calculation Charge per unit for Your Cleanroom

Showtime, designers must construct the required classification of the room based on ISO standards for particulate control.

- Air Changes Per Hr (ACH)

- Boilerplate Airflow Velocity

- Percent of fan filter unit of measurement coverage

"The reality is that at that place is no simple way to relate a cleanliness class level to a specific cleanroom air velocity or air change charge per unit because of complex factors to be considered in blueprint and operations. Information technology has been common in exercise and in ASHRAE and IEST's publications, however, to utilise cleanroom air velocities and/or air modify rates to quantify the amount of airflow requirements."

Lawrence Berkeley National Laboratory

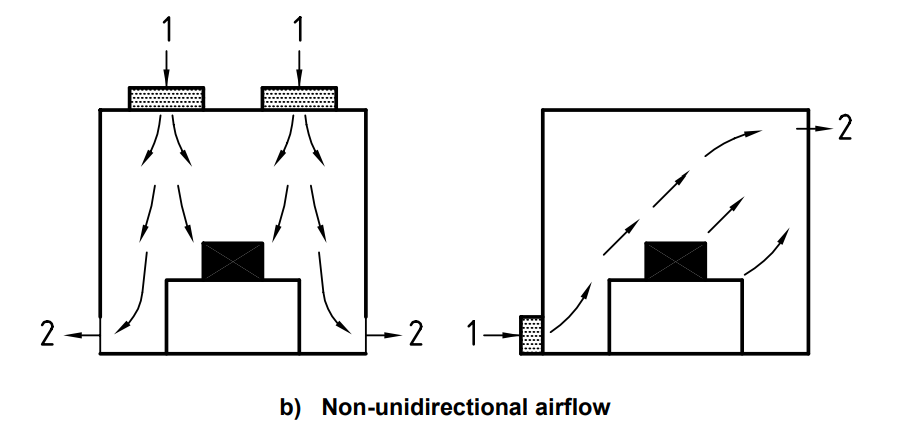

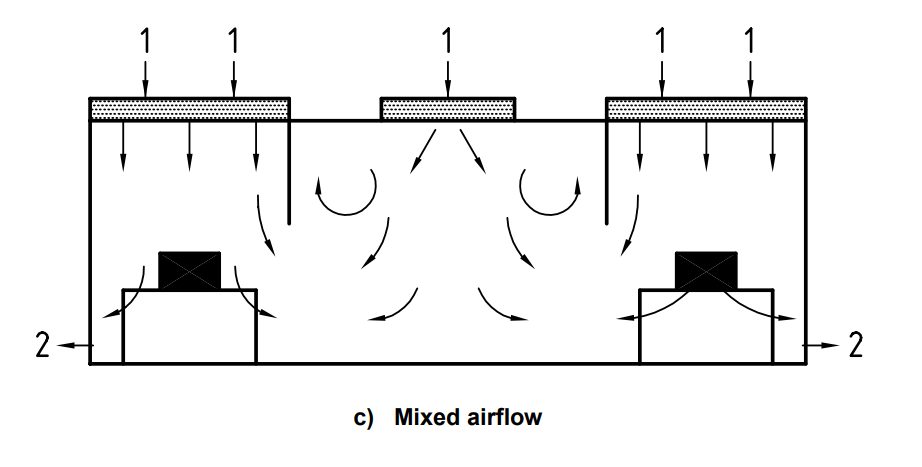

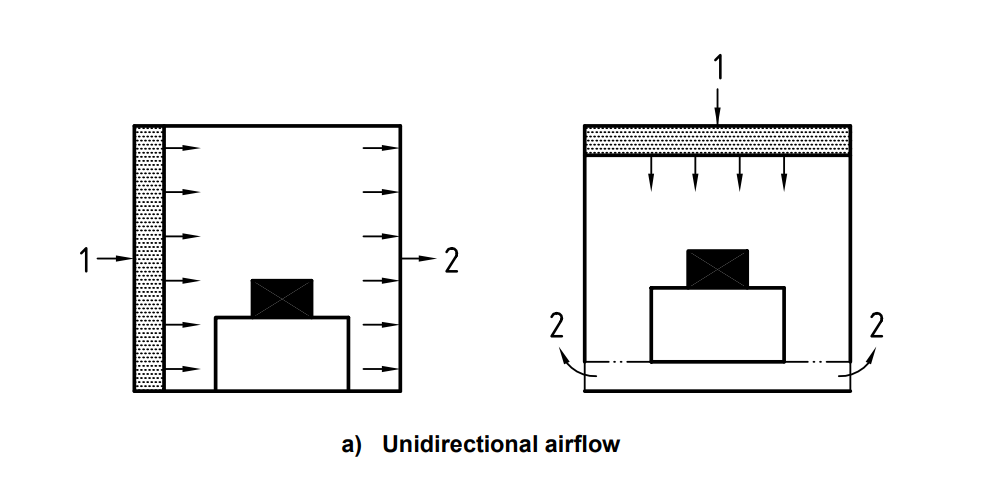

The cleanroom airflow pattern and HVAC pattern will determine which air change rate adding is appropriate. Turbulence, eddies, processes equipment, and pressure differentials all influence air exchange rates as exiting and returning air interact throughout the cleanroom. One must first consider whether the airflow design is unidirectional or not-unidirectional.

ISO standards outline unique air modify calculation methods for unidirectional vs non-unidirectional cleanrooms.

- In non-unidirectional and mixed flow cleanrooms, use the air changes per hour (ACH) adding method.

- In unidirectional airflow cleanrooms, calculate air change with boilerplate airflow velocity.

Calculating Air Change Rate (ACR) in Not-Unidirectional Cleanrooms (ISO 6 – ISO 8)

The chart below is institute within ISO 14644-4:2004 Pattern, Construction, & Start Up.

The calculation below is based on a ceiling meridian of 3 meters.

| Ceiling Meridian = 3.0 Meters | Low-End ACH (m3/m2 x h) | Loftier-End ACH (m3/m2 x h) |

| ISO half-dozen | 70 | 160 |

| ISO 7 | 30 | 70 |

| ISO 8 | 10 | twenty |

What is the Formula for Cleanroom Air Changes Per Hr (ACH)?

Calculate ACR with ACH when cleanroom airflow is non-unidirectional or mixed airflow.

The formula for calculating cleanroom ACH:

Air changes / hr = CFM 10 60min / Volume of Room

The charge per unit of cubic feet per infinitesimal is recalculated into cubic feet per 60 minutes, which is and so divided by the volume of the room (height X width Ten length).

Beneath we'll outline the basic principles of air change rates, but also provide a more rational outline of standardized air change tables for specific cleanrooms. Near chiefly, we'll aid you sympathize the proper air change calculation rate based on the industrial standards of your facility'due south cleanroom.

- Most non-unidirectional or mixed airflow cleanrooms autumn inside ISO five – ISO eight cleanrooms

- ACH calculations must arrange the calculation for ceiling pinnacle

- Applications: Pharmaceutical, health, biosciences, packaging, isolation, handling

Don't Use Air Velocity to Calculate Air Exchange in a Non-Unidirectional Cleanroom?

If the airflow in a cleanroom is not-compatible (non-unidirectional airflow) air velocity readings will not provide an authentic sample of inferential data points. Turbulence, eddies, processes equipment, and pressure differentials all influence velocity readings every bit exiting and returning air collaborate throughout the cleanroom. Information points would not represent a normal distribution of the bodily room conditions. Non-unidirectional air patterns measured with average velocity readings ofttimes produce confusing, misleading, or extraneous information.

Calculating Cleanroom Air Change Rates for ISO 1 – 5

In cleanrooms with unidirectional airflow, air substitution rate is calculated by air velocity sampling.

It's suggested that in cleanrooms with unidirectional airflow patterns (ISO CLASS 1 – 5), air exchange rates can be calculated by boilerplate air velocity. In some cases, ISO Class 6 cleanrooms may also require unidirectional air.

What is Unidirectional Air Flow?

Unidirectional airflow patterns behave horizontally or vertically across space in parallel movement, usually between lx – 90 FPM. Airflow remains within 18 degrees of parallel with sufficient velocity to sweep away particles before affixing to surfaces.

Unidirectional ACR Charts (Boilerplate Air Velocity)

| Velocity Threshold | ISO 5 | ISO 4 | ISO 3 | ISO 2 |

| Depression-Finish Velocity (Meters/2nd) | 0.2 | 0.three | 0.3 | 0.3 |

| High-End Velocity (Meters/Second) | 0.5 | 0.five | 0.v | 0.5 |

Cleanroom Applications for Average Air Velocity

- Benchmark for ISO two – ISO v facilities

- Cleanroom airflow is unidirectional

- Airflow velocity is independent of the ceiling meridian

- Electronics and microfab facilities

- Uniform velocity throughout the unabridged space

- Air flows through the unabridged cross-section of a make clean zone

- Steady velocity and approximately parallel streamlines of 60 – 90 FPM

- Directional airflow can be attained both vertically and horizontally.

Fan Filter Coverage for Unidirectional Cleanrooms

In most cases, a unidirectional airflow cleanroom requires ISO 5 or better air and most 100% fan filter ceiling coverage; fan filter coverage is not a specially revealing metric. Fan filter coverage is usually referenced in IEST, FED, and ASHRAE standards, nonetheless not referenced in latest ISO documentation for cleanroom design.

Equally noted previously, air changes per hour in unidirectional cleanrooms is calculated by air velocity readings. This is outlined in IES Standard RP CC 002-86 "Laminar Menses Clean Air Devices", which calculates the appropriate air velocity of a unidirectional cleanroom at ninety FPM.

All unidirectional cleanroom measurements will autumn (by and large) inside a 20% benchmark range of 90 FPM. A stock-still fan filter charge per unit of 90 FPM allows a cleanroom designer to simply install additional fan filter units as needed until arriving at the desired classification. The number of units required may vary throughout unlike bays of the facility. A facility could have up to 100 partitioned trophy, with one process happening in each bay.

Fan Filter Coverage for Non-Unidirectional Cleanrooms

Fan filter coverage is a common cleanroom benchmark outlined in Fed. Standard 209E (now outdated) and other case models.

The most common question nigh cleanroom construction — "How much is this going to price?". Establishing the baseline price of each fan filter *multiplied past* the number fan filter units per sq. foot simplifies cleanroom cost adding. One could regard fan filter coverage adding for cleanrooms as a quick reference tool in the early design stages.

Without knowing the ballpark quantity of fan filter units required for a cleanroom, estimating the cleanroom's initial cost is challenging. The performance and cost of a fan filter unit of measurement vary, hence fan filter coverage estimates are helpful for cleanroom specialists after establishing other criteria.

Fan filter coverage charts help simplify the dialogue between preliminary engineers and finish-users (buyers) and brand quotes more transparent. The final operation nevertheless requires the input of many other variables.

Summary: Fan filter coverage calculation is not referenced by ISO cleanroom blueprint standards. Information technology'south a valuable tool for specialists to quickly approximate build costs. Fan filter coverage provides a simple way to calculate cleanroom construction costs during preliminary applied science, but it is considered a secondary gene to the final efficiency and performance of the cleanroom.

How Do Nosotros Calculate Fan Filter Coverage?

No. of FFUs = (Air Changes/Hour ÷sixty) x (Cubic ft. in room÷ FFU CFM*)

Cleanroom Air Change Rates and Tables for USP Standards

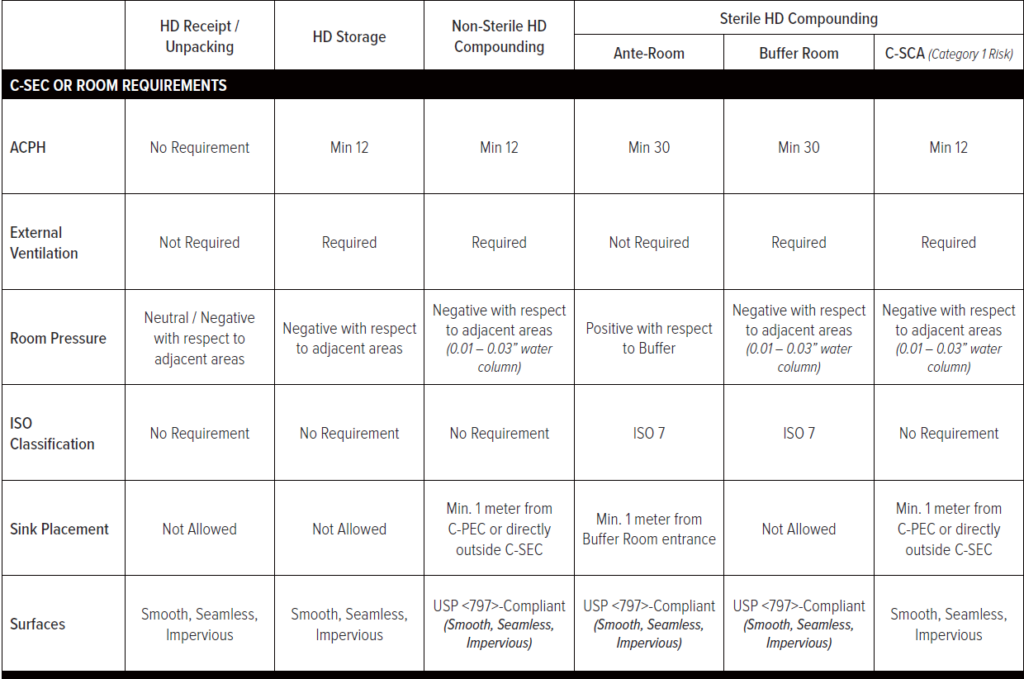

USP 797 and USP 800 cleanrooms for sterile and hazardous drug processes as well have unique air change requirements. A menstruum hood within the primary control area does, in fact, influence the overall air change rate of the room equally a whole. Sterile or chancy compounding has a much different airflow requirement than a microelectronics cleanroom.

Cleanroom Air Commutation Calculation Variables

These models are about common considering they are hands referenced during preliminary engineering. The terminal calculation requires more than thorough means to accomplish ISO recovery rates, and ensure that airborne particulate levels rarely exceed class limits. For instance, a decay equation measures particulate betwixt the first and second test sampling. This helps cleanroom designers empathize particulate levels after a doorway or laissez passer-throughs opens and closes. Further variables, such as dispersion rates from personnel and machinery, additional clean air devices, surface deposition, and air treatment design besides influence the last particle contributions.

Why Practise Cleanroom Air Change Rates Vary Despite ISO Cleanroom Standards?

Cleanroom ACH requirements are largely determined past contamination levels. A cleanroom built at the low cease of air change benchmarks may be adequate when the cleanroom requires few operators during relatively make clean processes.

Facilities business relationship for particulate expectations by extending air change rates, or sometimes with built-in, variable airflow systems. Some cleanroom facilities opt for demand-controlled filtration systems which optimize air recirculation based on real-time particle counts. As well, variable drive fan filter provides parameters for preset adjustment in the case that a cleanroom is vacant for extended periods. Considering cleanrooms generally remain powered 24/vii, throttling back fan drives reduce overall energy toll.

Why is Cleanroom Air Change Based on a Range?

In about every example, the air alter charge per unit is established by a low and high range for a simple reason…it's not an exact science.

The high end (48 ACH) of an air exchange rate in an ISO viii cleanroom is nearly 9 times cleaner than the depression end (5 ACH) of 146144-four standards. This doesn't provide a lot of clarity for contractors or projection leads when budget, product safety, or operating cost is of paramount importance.

Air change tables suggest a high and depression range because these tables practice non account for complexities of achieving a final cleanliness level in a specific cleanroom. Further, some facilities may over-spec their air system for more than favorable temperature and humidity control. However, in nigh cases, facilities build toward the lower end of the threshold to maximize air efficiency. Nonetheless, air change tables allow a gross gauge of the size and quantity of fan filter units, which is a pregnant factor in the overall cost per foursquare foot.

A Reliable Test Result Requires a Reliable Test Method.

It must be known that non every calculation method is advisable for every facility. Depending on the design of the cleanroom and HVAC components at paw, the above adding methods require clarity and justification.

Benchmarks establish guidelines and best practices, still, the ACR of a cleanroom in move is more variable than 1 would think. Project leads and contractors often lack information for comparing of build variation within high-tech or niche manufacturing facilities. Factors include the utilise of air handlers vs modular fan filter systems, the efficiency of filters and motors, variable air change rates per expanse, and overall pressure resistance.

"There is no understanding on a recommended ACR rate. About sources suggest a range of rates, while these ranges tend to be wide and practise not provide clear guidance to designers who need to select a set up ACR value to specify equipment sizes."

US Dept. of Energy Study

Why Might a Facility Avoid Generic Tables for ACR Benchmarks?

An aggressively designed airflow rate requires a more powerful HVAC organization, more than fan filter coverage, and extends overhead operating costs. Sometimes a process quickly evolves toward smaller and more than sensitive components, or a facility expects increased output and sensitivity in the almost futurity. An oversized air handling system easy mediates air need when product scales, requires a cleaner classification or involves expanding the number of cleanroom suites.

Air Change Rates 2.0

A cleanroom design incorporates the analysis and deliberation at every intersection between manufacturers, architects, engineers, HVAC specialists, and facility operations staff. Air modify tables often provide points of inference and consideration but have no traceable technical ground for contagion control. Initial estimates of air exchange rates must reflect terminal conditions and suit for less obvious parameters such equally the commencement of heat gains, air leakage, and recovery rate,

Air change tables are important tools during initial discussions, however, efficiency and cleanliness take far more than elusive parameters than square footage, average airflow velocity, or hourly air change rates. Experienced cleanroom designers understand that other factors such as proper fan size selection, area coverage, and room design accept nefarious consequences if not considered early. A cleanroom organization requires many co-dependent evaluations and preliminary decisions for a strong foundation.

Conclusions

- In non-unidirectional and mixed flow cleanrooms, employ the air changes per hour (ACH) calculation method.

- In unidirectional airflow cleanrooms, calculate air alter with boilerplate airflow velocity.

The central goal of each cleanroom is unique to its procedure, and and then is the scientific discipline behind its design. For most facilities, speaking with a controlled surroundings specialist is the fastest path from clean idea to a clean build.

The information herein should aid you practice two things: clarify and justify an air exchange rate calculation method, and understand which is most applicable for your cleanroom. Withal, it does not found a recommendation for your cleanroom.

Accept questions? Get in touch on with our controlled environment specialists.

Related Posts

-

-

-

Cleanroom Fan Filter Units vs Air Treatment Units

A cleanroom air treatment unit (AHU) is a cornerstone of temperature, humidity, and pressurization within controlled environments. Today, modular fan filter units allow more adaptable configuration with simplified maintenance process. Both systems serve conditioned and…

-

Cleanroom Construction FAQ

Definitive Cleanroom Construction FAQ: How much does a cleanroom cost? How does the level of ISO classification affect build and operating costs? How much supporting space will I need for a cleanroom add-on or ISO…

-

-

CleanPro® Turnkey Cleanroom Install

CleanPro's plough-key cleanroom solution provided a ane-stop, one-contact upshot for the initial commitment and on-site installation of walls, ceiling grids, electrical systems, floor, filters, HVAC, and more than.

Source: https://blog.gotopac.com/2019/05/24/the-truth-about-cleanroom-air-change-rates-calculations/

Posted by: arguetamonatur.blogspot.com

0 Response to "How Much Air Needs To Circulate In Clean Room?"

Post a Comment